To maintain your fuel tanks effectively, focus on five key areas: regular visual inspections with detailed documentation, proactive water detection and contamination prevention, professional cleaning to remove sediment buildup, consistent fuel quality testing, and timely system component maintenance. Keep tank levels above 20%, check monthly for water infiltration, and partner with certified professionals for thorough analysis. These practices will save thousands in repairs while protecting your valuable fuel investment – discover how each strategy maximizes your operational efficiency.

Regular Tank Inspection and Documentation

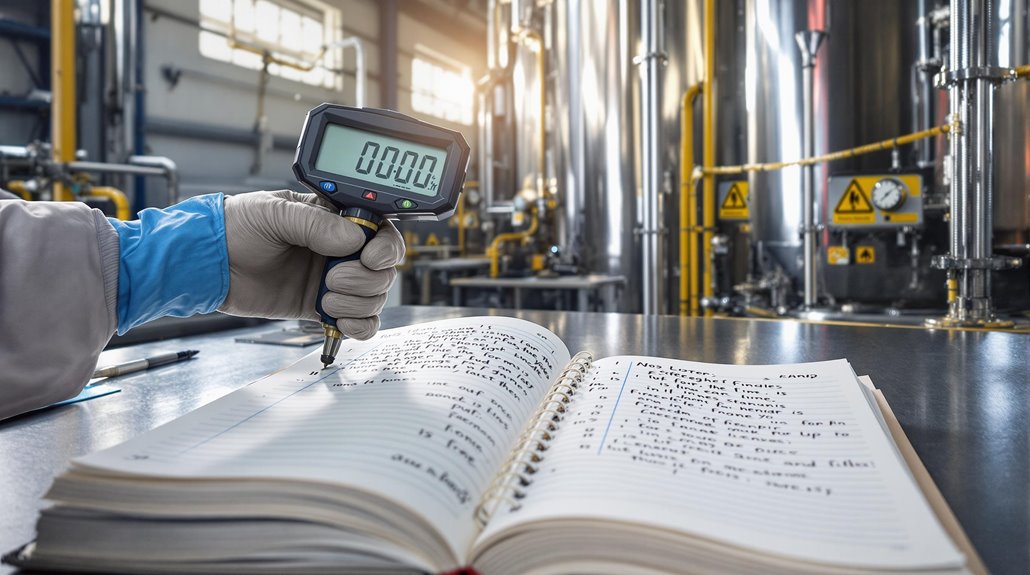

While maintaining fuel tanks might seem challenging, establishing a regular tank inspection routine is essential for every business owner who manages on-site fuel storage.

You’ll need to schedule monthly visual checks and quarterly detailed inspections of your tanks, looking for signs of wear, damage, or potential leaks.

To keep your documentation practices organized, create a digital logbook where you’ll record all inspection dates, findings, and maintenance actions.

Make sure you’re tracking important details like:

- Tank pressure readings

- Fuel levels and quality tests

- Condition of seals and valves

- Any repairs or replacements made

- Photos of potential problem areas

Don’t forget to maintain these records for at least three years, as they’ll prove invaluable during regulatory audits and help you spot developing issues before they become serious problems.

Water Detection and Contamination Prevention

Building on your inspection practices, regular water detection and contamination monitoring represent the next critical line of defense for your fuel storage system.

You’ll need to check for water presence using water-finding paste or electronic sensors at least monthly, as water can lead to microbial growth and fuel degradation.

Common contamination sources include:

- Condensation from temperature changes

- Faulty tank caps or seals

- Ground water seepage

- Precipitation during fuel delivery

To prevent contamination, you should:

- Install and maintain quality water filters

- Keep tank levels above 20% to minimize condensation

- Use fuel stabilizers when appropriate

- Clean fuel dispenser nozzles regularly

- Test fuel quality quarterly

If you detect water, don’t wait – remove it immediately using a pump or water-absorbing filter to protect your fuel quality and equipment.

Professional Cleaning and Sediment Removal

Even though regular inspections help prevent major issues, professional tank cleaning remains essential for removing accumulated sediment and sludge that naturally builds up over time.

You’ll want to establish consistent cleaning schedules and use appropriate fuel additives to maintain ideal tank conditions between professional services.

When it’s time for professional cleaning, here’s what you can expect:

- Complete tank draining and inspection using specialized equipment to assess sediment levels and tank integrity

- High-pressure washing of interior surfaces with industrial-grade cleaning solutions that break down stubborn deposits

- Thorough removal of all contaminants, followed by proper disposal according to environmental regulations

Remember to document each cleaning service and maintain detailed records of sediment removal, which will help you enhance your maintenance intervals and demonstrate compliance with industry standards.

Monitoring Fuel Quality and Testing

Regular monitoring of your fuel quality through systematic testing helps prevent costly equipment damage and guarantees maximum performance of your fuel storage system.

You’ll want to implement monthly fuel testing to check for water content, microbial growth, and contaminants that could harm your equipment.

Consider these essential quality monitoring steps:

- Test fuel samples from different tank levels

- Check for proper fuel coloration and clarity

- Measure particulate levels and contamination

- Verify fuel meets industry specifications

- Document all test results for tracking

It’s smart to partner with a certified lab for thorough analysis, especially for diesel fuel which can deteriorate over time.

When you maintain consistent quality monitoring, you’ll extend equipment life, optimize fuel efficiency, and avoid unexpected downtime that could impact your business operations.

System Component Maintenance and Upgrades

While monitoring fuel quality helps prevent system failures, maintaining and upgrading your tank’s physical components is equally important for long-term reliability.

You’ll want to regularly inspect and maintain key system elements to avoid costly repairs down the road. Consider implementing these essential fuel system upgrades and maintenance practices:

- Schedule annual inspections of pipes, valves, and fittings to catch potential leaks or wear before they become serious problems

- Replace aging components like filters, seals, and gaskets according to manufacturer recommendations, even if they haven’t failed yet

- Install modern monitoring equipment to track fuel levels, temperature, and pressure in real-time, helping you spot issues early

Remember that component replacement costs are typically much lower than dealing with system failures or environmental cleanup from preventable leaks.

Conclusion

By following these essential fuel tank maintenance tips, you’ll keep your business running smoothly while protecting your valuable fuel investment. Regular inspections, contamination prevention, and professional cleaning create a solid foundation for tank health. When you combine these practices with quality monitoring and system upgrades, you’re not just maintaining equipment – you’re safeguarding your operation’s lifeblood and ensuring reliable performance for years to come.