You’ll get the best cold-weather performance from your heavy equipment by choosing synthetic lubricants that maintain proper viscosity in extreme temperatures. Look for products specifically designed to flow well down to -40°F, like synthetic PAO or lithium complex greases. Increase your lubrication frequency during winter months, and always conduct thorough inspections before starting equipment. The right combination of oils and maintenance practices will protect your valuable machinery throughout the coldest conditions.

Understanding Cold Weather Impact on Equipment Lubrication

When winter temperatures plummet, your heavy equipment faces unique lubrication challenges that can seriously impact performance and longevity. The cold impact on your machinery’s lubricants creates several issues you’ll need to address, including increased oil thickness and reduced flow rates.

You’ll notice that cold temperatures make lubricants more viscous, which means they won’t flow as easily through your equipment’s components. This can lead to delayed lubrication during startup, causing excess wear on critical parts.

The lubrication challenges don’t stop there – cold weather can also cause:

- Moisture accumulation and ice formation in systems

- Seal contraction and potential leaks

- Reduced protection against metal-to-metal contact

- Slower response times in hydraulic systems

- Formation of wax crystals in some oil types

Key Properties of Cold-Weather Lubricants

As your equipment faces harsh winter conditions, you’ll need lubricants specifically designed with properties that combat cold-weather challenges. The two most vital properties to look for are cold flow capability and viscosity index.

A high viscosity index means your lubricant will maintain its thickness across a wide range of temperatures, which is fundamental for protecting your equipment’s moving parts. You’ll want to verify your lubricant has excellent cold flow properties, allowing it to move freely even in freezing conditions.

Other key properties to take into account include:

- Pour point (lowest temperature at which oil flows)

- Low-temperature pumpability

- Shear stability

- Resistance to oxidation

These properties work together to keep your equipment running smoothly through winter’s toughest conditions, preventing costly breakdowns and extending component life.

Top Synthetic Oil Options for Sub-Zero Conditions

Since operating heavy equipment in sub-zero temperatures demands exceptional lubrication, synthetic oils have become the go-to choice for equipment operators and fleet managers.

You’ll find that synthetic oil benefits include superior flow characteristics and enhanced protection against wear, even in the most challenging conditions. When you’re working in extreme temperatures, these specialized lubricants maintain their viscosity and performance far better than conventional oils.

- Picture your hydraulic system running smoothly at -40°F, with synthetic oil flowing effortlessly through essential components.

- Imagine starting your equipment instantly on a frigid morning, as the synthetic oil reaches critical parts within seconds.

- Visualize your machine’s engine parts staying pristine and protected, even after hours of operation in bitter cold.

Recommended Greases for Arctic Operations

Many specialized greases excel at protecting heavy equipment in extreme arctic conditions, where standard lubricants simply can’t perform. You’ll want to guarantee grease compatibility when switching between products, as mixing incompatible greases can cause equipment failure.

| Grease Type | Temperature Range | Environmental Considerations |

|---|---|---|

| Synthetic PAO | -60°F to 350°F | Biodegradable options available |

| Lithium Complex | -40°F to 325°F | Standard disposal required |

| Calcium Sulfonate | -65°F to 400°F | Low toxicity, marine-safe |

When selecting arctic greases, you’ll need to evaluate factors beyond just cold weather performance. Modern formulations offer excellent pump ability in extreme cold while maintaining environmental considerations. Look for products specifically tested in arctic conditions, and always check the manufacturer’s temperature ratings before making your final selection.

Hydraulic Fluid Selection for Extreme Cold

When temperatures plunge below freezing, your heavy equipment’s hydraulic system needs specialized fluids that won’t thicken or gel.

You’ll want to choose a hydraulic fluid with excellent cold viscosity properties to guarantee smooth operation in arctic conditions. Look for fluids specifically rated for extreme temperatures, as they’ll maintain proper flow characteristics even at -40°F.

- Picture your hydraulic fluid flowing like water through the system, not thick molasses that could damage your pumps.

- Imagine the fluid maintaining its consistency like warm syrup, even when everything else is frozen solid.

- Think of your equipment starting up instantly on a frigid morning, with no delays from thick, sluggish fluid.

Consider switching to synthetic hydraulic fluids during winter months, as they typically offer better cold-weather performance than conventional mineral-based options.

Maintenance Tips for Cold Weather Lubrication

Proper cold weather lubrication maintenance requires three essential steps to keep your heavy equipment running smoothly through winter.

First, you’ll need to increase your lubrication frequency since cold temperatures can cause lubricants to thicken and become less effective. Schedule greasing sessions more often than you’d during warmer months.

Next, conduct thorough equipment inspections before each shift to check for frozen components or areas where lubricants might’ve thickened excessively. Pay special attention to joints, bearings, and other moving parts that are vital for operation.

Finally, maintain detailed records of your cold weather maintenance activities. Track when you’ve performed lubrication services, note any unusual findings during inspections, and document how your equipment responds to different lubricants in various temperature conditions.

This data will help you optimize your winter maintenance routine.

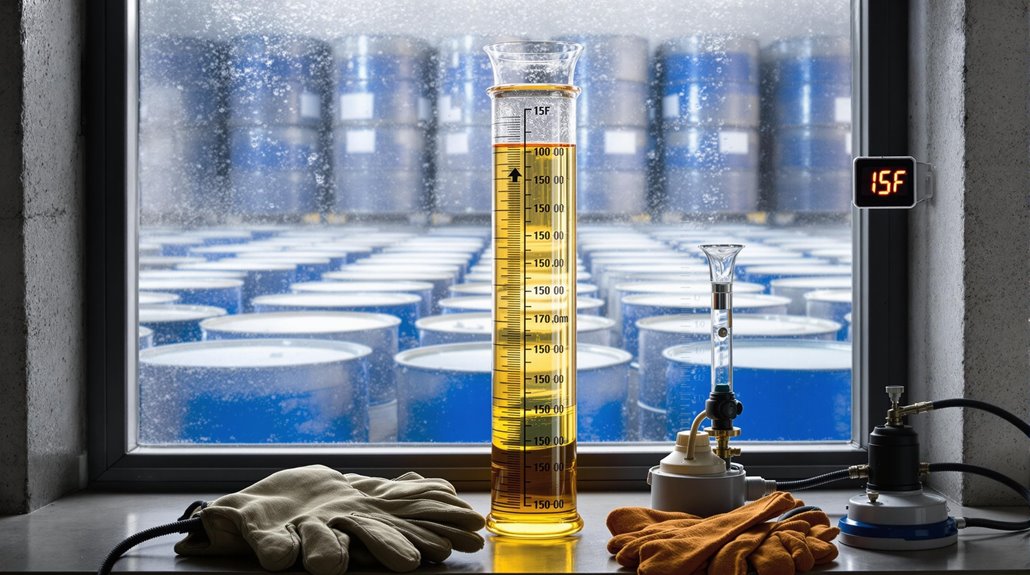

Storage and Handling Guidelines for Winter Lubricants

Since winter lubricants require special care to maintain their effectiveness, establishing proper storage and handling procedures is essential for your equipment’s performance.

When implementing storage techniques, you’ll need to maintain consistent temperatures and protect containers from moisture contamination. Your handling precautions should include regular inspection of storage areas and proper container sealing to prevent degradation.

- Store your winter lubricants in a temperature-controlled environment between 40-70°F, using shelving units that keep containers off the ground and away from direct sunlight.

- Label all containers clearly with product type, date received, and expected shelf life, making rotation and inventory management easier.

- Keep dedicated pumps, funnels, and transfer equipment for each type of lubricant to prevent cross-contamination and maintain product integrity.

Cost-Benefit Analysis of Cold-Weather Lubricants

Although cold-weather lubricants cost more upfront than standard options, they’ll typically save you money in the long run through reduced equipment wear and fewer repairs.

When you conduct a cost analysis, you’ll find that specialized winter lubricants can improve your lubricant efficiency by up to 30% compared to conventional products.

Consider these key financial benefits:

- Lower fuel consumption due to reduced friction

- Extended equipment lifespan

- Fewer emergency repairs and downtime

- Decreased labor costs for maintenance

While you might pay 15-25% more for cold-weather lubricants initially, you’ll often recover these costs within the first season of use.

Your equipment will start more easily in frigid conditions, and you’ll notice smoother operation throughout the winter months, leading to significant long-term savings.

Conclusion

You’ll find that proper preparation prevents poor performance when it comes to cold-weather lubrication for your heavy equipment. By selecting superior synthetic oils, maintaining meticulous maintenance schedules, and storing supplies safely, you can keep your machinery moving smoothly through the harshest winter conditions. Remember to regularly review your lubrication strategy as temperatures tumble, ensuring your equipment stays efficient and protected all season long.